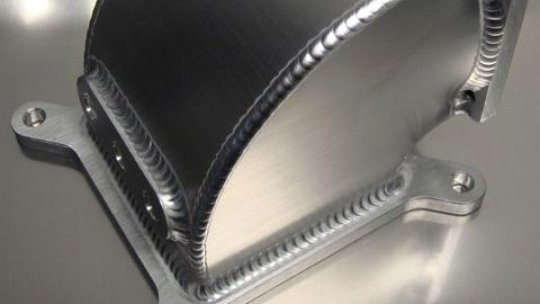

TIG lassen heeft vele voordelen tegenover andere lasprocessen en is daarom door ons het meest gebruikte lasproces. Door de uitgebreide bedienings mogelijkheden en de goede beheersbaarheid van de vlamboog kan zeer comfortabel, mooi en schoon worden gewerkt. De geringe vervorming van het werkstuk, de smalle laszone en de spatvrije vlamboog zorgen voor schone, exacte lasnaden zonder insluiting van slakken en zonder noodzakelijke afwerking. De lasdraad word met de hand toegevoegd en op die manier is het las uiterlijk mede te bepalen. Het TIG lasproces word door ons ook toegepast bij couveuse laswerk.

MIG-MAG lassen geeft een grote lassnelheid en geringe vervorming welke zorgen voor grote rendabiliteit, over het algemeen betekent dit goedkoper voor de klant. De grote sterkte van de lasnaad, de uitstekende eigenschappen bij het lassen van dunne plaat en de eenvoudige en veilige hantering bij staal, Rvs en aluminium maken het proces universeel. De lasdraad word automatisch toegevoegd maar de las is over het algemeen wel wat groffer en groter dan bij het TIG proces en moet vaak nabewerkt worden.

BMBE-lassen is voor bijna alle lasbare materialen toe te passen. Lassen met beklede elektroden is eenvoudig en veilig en de compacte apparaten zijn probleemloos te bedienen en eenvoudig te transporteren voor klussen op locatie. Omdat er geen gas nodig is, kan ook in de openlucht, zelfs met slecht weer en harde wind, worden gelast en dat is dan ook voornamelijk waar wij indien noodzakelijk dit proces voor gebruiken. Daarnaast gebruiken we deze lasmethode ook nog deels voor het lassen aan gietijzer.